Spindle Speed Calculator

Introduction:

Calculating spindle speed is crucial in machining operations to ensure optimal performance and tool life. A Spindle Speed Calculator simplifies this process, allowing users to determine the rotational speed needed for a cutting tool. In this article, we’ll provide a functional Spindle Speed Calculator, along with explanations on how to use it effectively.

How to Use:

- Input Parameters:

- Diameter of the cutting tool (D)

- Cutting speed (S)

- Enter Values:

- Input the diameter of the cutting tool in millimeters.

- Input the cutting speed in meters per minute.

- Click Calculate:

- Click the “Calculate” button to obtain the spindle speed.

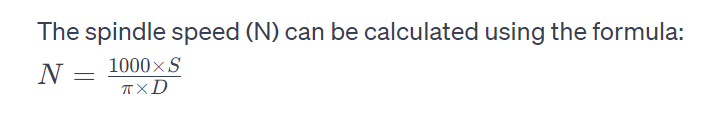

Formula:

Where:

- N is the spindle speed in revolutions per minute (RPM).

- S is the cutting speed in meters per minute.

- D is the diameter of the cutting tool in millimeters.

Example Solve:

Suppose we have a cutting tool with a diameter (D) of 10 mm and a cutting speed (S) of 200 m/min.

N≈6366RPM

Therefore, the required spindle speed is approximately 6366 RPM.

FAQs:

- What units should be used for input values?

- Input the diameter in millimeters and the cutting speed in meters per minute.

- Is the calculator suitable for specific materials?

- Yes, the calculator works for various materials as long as the appropriate cutting speed is provided.

- Can I use the calculator for different machining processes?

- Absolutely, the calculator is versatile and applicable to various machining operations.

Conclusion:

A Spindle Speed Calculator is a valuable tool for machinists, helping them determine the optimal spindle speed for cutting tools. By inputting the diameter and cutting speed, users can quickly obtain the required RPM. The provided simplifies the process, making it accessible for both beginners and experienced machinists.