Plunge Rate Calculator

Introduction

In the realm of engineering and machining, precise calculations are indispensable. One crucial computation often required is the determination of plunge rates, particularly in milling operations. Plunge rate refers to the rate at which a cutting tool penetrates into the workpiece material. It plays a significant role in ensuring efficient material removal while preventing tool wear and workpiece damage.

How to Use

This article presents a simple yet effective plunge rate calculator that enables users to swiftly ascertain the optimal plunge rate for their machining tasks. The calculator allows users to input essential parameters such as feed rate, spindle speed, and desired chip load, providing them with accurate plunge rate results.

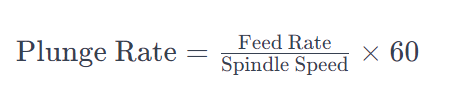

Formula

The plunge rate calculation involves the following formula:

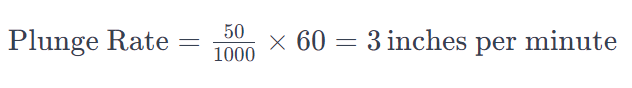

Example Solve

Suppose we have a milling operation with a feed rate of 50 inches per minute and a spindle speed of 1000 RPM. Let’s calculate the plunge rate using the formula:

FAQs

Q: What is the significance of plunge rate in machining?

A: Plunge rate directly impacts machining efficiency, tool life, and surface finish. It determines how rapidly the cutting tool enters the workpiece material, influencing chip formation and heat generation.

Q: How does the plunge rate affect machining operations?

A: An optimal plunge rate ensures efficient material removal without overloading the tool or causing excessive heat buildup. It helps maintain dimensional accuracy and surface integrity of the workpiece.

Q: Can the plunge rate vary for different materials and tool geometries?

A: Yes, plunge rate requirements may differ based on the material being machined, tool geometry, cutting conditions, and desired surface finish. It’s crucial to adjust the plunge rate accordingly for optimal results.

Conclusion

In conclusion, the plunge rate calculator provided in this article offers a convenient tool for engineers, machinists, and hobbyists engaged in milling operations. By accurately determining the plunge rate, users can enhance machining efficiency, extend tool life, and achieve superior surface finishes. Incorporating this calculator into machining workflows can lead to improved productivity and precision.